Project Description

Electro Plating Services

Madison Heights, Michigan

Project Details

DATE OF COMPLETION

November 2023 (completed in 12 working days)

PRIME CONTRACTOR

ENGINEER

PROJECT TYPE

ISCR

PROJECT DESCRIPTION

In-situ treatment of 2,565 cubic yards of soil contaminated with Hexavalent Chrome, PFAS and VOC’s using FB-HCZ, FB-H40, liquid PAC and hydrated lime

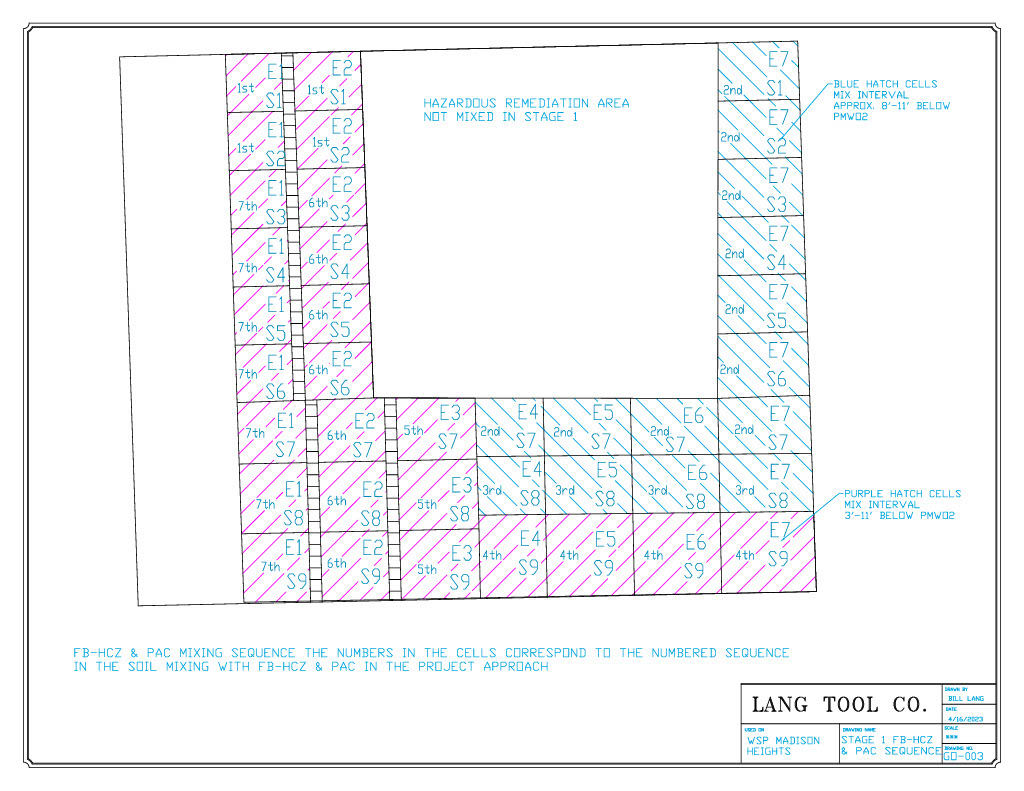

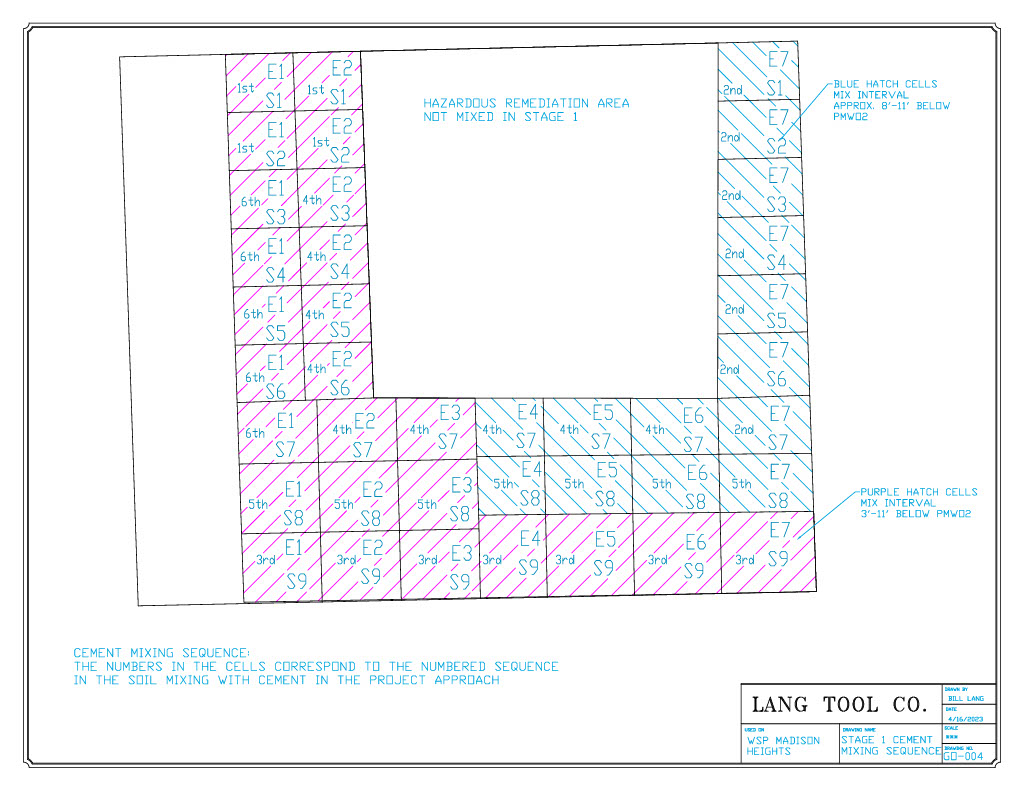

Stage 1 was treating the area in the drawings above with 5% FerroBlack-HCZ & 1% Powdered Activated Carbon in a 30% solution. Note that there were two different mixing intervals- 8-11’ below monitoring well PM02 and 3-11’ below the well. ASI performed the excavation prior to the commencement of soil mixing. This portion of the mixing was completed in 5 working days. After this stage of mixing was completed there was a two week waiting period for the chemical reaction to complete. The area was then treated with 5.3% Portland cement and left in place. The stabilization with cement was completed in two working days.

Lang Tool Co. developed the delivery plant for FB-HCZ & liquid PAC. Both reagents were delivered to the site in 3,000 lb. totes. The plant is equipped with 2 air operated diaphragm pumps and 3 platform scales for accurate delivery. The unit has its own rotary air compressor & small generator to operate the scale computer. It is completely self-contained.

At left the Dual Axis Blender is finishing the FB-HCZ/PAC stage of the work. Above is the LTC ISS plant. It mixes, meters and pumps the cement for the cement step of the process. The ISS Plant was also used to pump the lime for the last stage of this project.

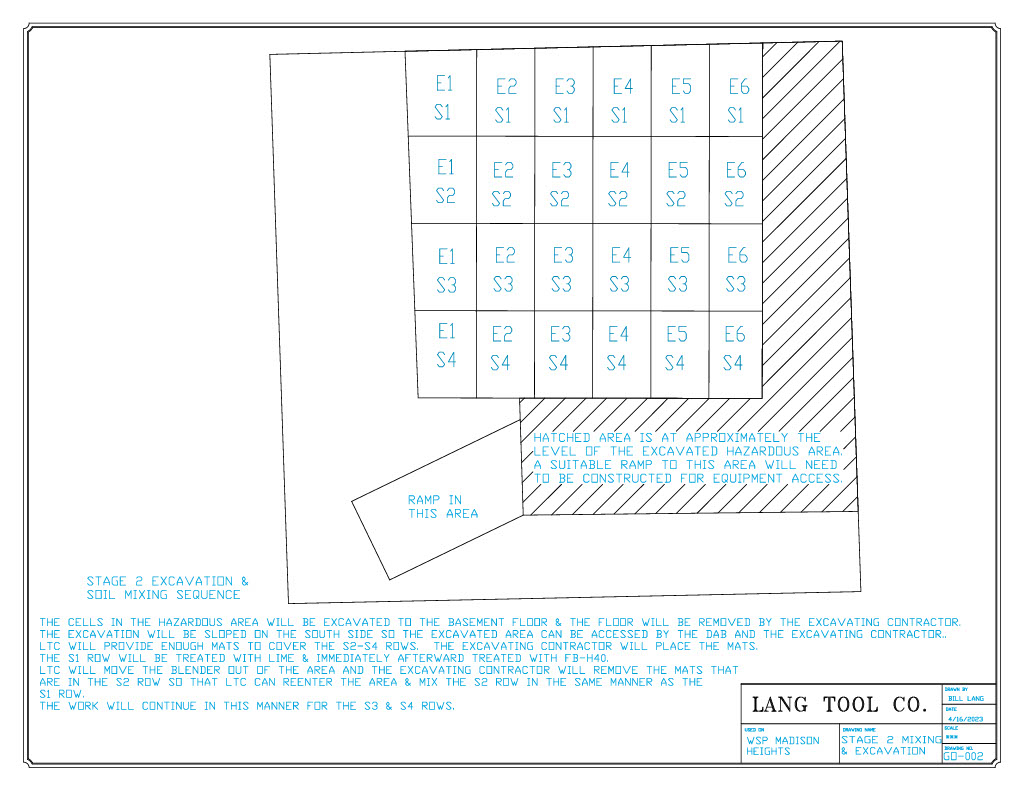

This project was often referred to as the Green Ooze project because in 2019 green slime began to run out of the bank on I-696. The ooze was coming from this site. Above, the Dual Axis Blender is mixing in the last section of the job.