Project Description

Philadelphia Former Dow Site

Philadelphia, Pennsylvania

The following presentation features an ISS/ISCO project that Lang Tool Co. performed in Philadelphia. ISS/ISCO soil mixing uses persulfate activated with Portland cement. A persulfate solution is mixed in tanks on the ISCO Mixing Plant and pumped in controlled quantities to the ISS Mixing Plant where it is mixed with cement and pumped to the LTC Dual Axis Blender. The blender mixes the slurry into the contaminated soil. This process is extremely efficient as it accomplishes both ISS and ISCO in one pass. The project involved 4,500 cubic yards of mixing & was completed in 7 working days.

On this project the top 3 ½’ of soil was clean and did not require treatment. When this upper layer was removed the interval that required treatment was saturated as you will see in the presentation. With only an ISCO approach the site would have been too wet to do anything with for a long period of time. The ISS/ISCO approach made it possible to use the site immediately after the ISS/ISCO procedure was completed.

ISS/ISCO is extremely efficient as it eliminates remote stockpiling of the clean soil and returning the stockpiled soil at a later date reducing the project timeline and costs. This process is shown in detail in the presentation. ISS/ISCO has the added remedial advantage of reducing the hydraulic conductivity of the soil.

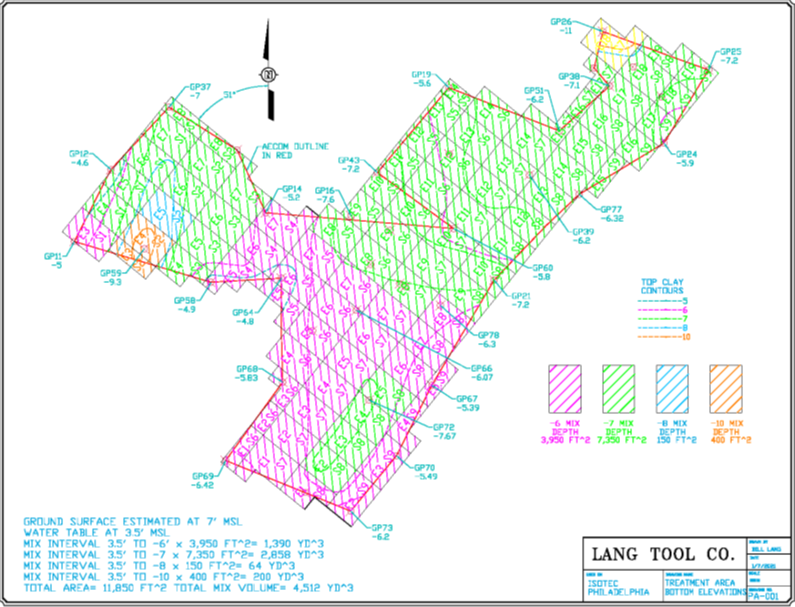

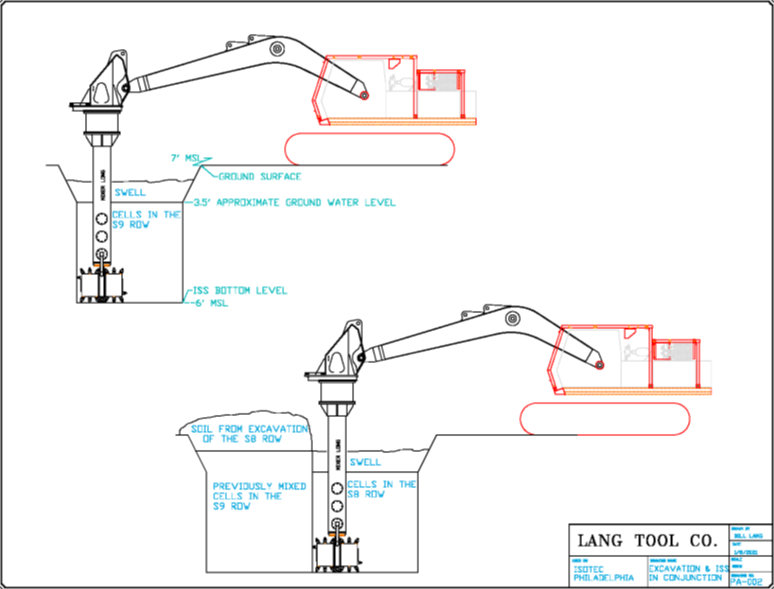

The soil above the water table was determined to be clean. ISS/ISCO was required from 3.5’ MSL to the various

elevations shown on PA-001. To avoid the double handling associated with stockpiling the clean soil Lang Tool

Co. excavated the clean soil from the S9 row and placed it immediately adjacent to the south side of the S9 row.

Treatment on the S9 row was started. The next morning clean soil was excavated from the S8 row and placed

on the treated soil in the S9 row. The work continued in that manner until ISS/ISCO was completed on the

entire site. This extremely efficient procedure greatly reduces project costs.